|

|

|

Date |

Event |

|

01/04/2006 4hrs Door Sills\ Floorboards

Rear Bulkhead |

Fitting the RH sill guard is going to involve

moving the car which is currently up on axle stands. Since the RH sill guard

is already drilled and I know it will fit it can be fitted anytime. In

terms of productivity it was more important to complete the fitting of the

floor boards and the rear bulkhead in preparation fro the final

fitting of the transmission and gearbox covers. I removed the floor boards

and laid down a bed of sealer. I refitted the floorboards , securing

them with stainless countersunk screws. I wiped away any surplus

sealer with a damp cloth. I then checked all edges above and below the

chassis to fill any gaps with sealer and removing the surplus again with a

damp cloth.

I temporarily fitted the rear bullhead and

marked it's position on the floor boards and down the inside of the rear

body shell. This was to give me a guide to laying down the sealer. I removed

the bulkhead and laid down a bed of sealer on the rear cross member, the

floor boards and down the side of the rear body I put the rear bulkhead in

place and secured it with M5 countersunk screws and penny washers . On the

curved section of the bulkhead the buts against he inside of the wheel

arches I used M5 countersunk screws and penny washers each side of the

GRP secured with M5 Nyloc nuts. Where necessary I dished the penny

washer to match the curve of the wheel arches and bulkhead. With

the rear bulkhead in place I filled any remaining gaps and

cleaned off any surplus sealer with a damp cloth.

|

|

02/04/2006

3hrs Floorboards Transmission Cover |

I took another look at the floor boards and

rear bulkhead and filled a couple of places I had missed in he wheel arches

and next to the inner seat belt anchorages.

I temporarily fitted the gearbox and

transmission covers and marked there position on the floor boards so

that I knew where to position the foam seals. I found out that I could

make neat holes in the foam sealer with a single hole punch. before

fitting the foam seals to the bulkhead and the floor boards I fitted 5 x M8

Rivnuts to the predrilled holes in the bulkhead. I temporarily fitted

the foam seal to the bulkhead, punching holes in it to line up with the

rivnuts. Satisfied with the line and length I peeled off the backing

paper starting at one end and as far as the first securing hole.

I attached the seal to the bulkhead pressing it firmly i place and making

sure that the holes were still aligned by inserting an M8 bolt through the

seal in in to the rivnut. I then removed the next section of backing tape

and repeated the operation and so on until I reached the far end.

|

|

17/04/2005

4hrs Transmission Cover |

Bank Holiday Monday and at last I was able to

get some time in the garage. I perceived that there would be a

potential problem fitting the transmission (Prop Shaft Cover).

With the floor boards in place the edge of the chassis can not be seen. the

transmission cover runs at an angle across the car. There was a

distinct possibility that securing holes drilled in each side could strike

the edge of the chassis plate underneath unless I was are careful and worked

out where to drill the holes, so that they were either completely in the

wood of the floor boards or in the metal of the chassis. I

put masking tap on to the floor boards and marked on it hit position of the

cover. I used a small off cut of metal to to gauge the

distance of the edge of the floor boards to the chassis plate. I

transferred thee marks to the masking tape so that I could see the

approximate line of the edge of the of the chassis in relation to the

flanges of the cover. I then worked out where to drill the holes

so that they avoided the edge of the chassis plate . I found that if holes

were place 1.0" from the front and at at the centre point of the cross

member at the back with subsequent holes on 7.0" centres between

them. Because every car is different and probably every cover is

different these measurements are only a guide and would need to be

determined. I transferred the marks to the cover and drilled small pilot

holes . I fitted the cover and marked through the pilot holes back on to the

chassis. For the most part they lined up but I had to adjust the

position of a couple of them to make sure they missed the edge and were

located in the metal of the chassis. I drilled the chassis with

3mm drill gradually opening it out to 4.2mm and then tapped the chassis to

accept M5 PAN head screws. those holes drilled through the floor board

were drilled to M5 clearance and secured with pan head bolts, penny washers

and nyloc nuts. i took the cover off for painting. I

believe that I might still have to slot the front holes in the cover to

improve the final fit of the gearbox cover over the transmission

cover.

|

|

23/04/2006

3hrs Gearbox Cover |

Not much progress over the past week. I

slotted all the securing holes in the prop shaft cover to accommodate

squeezing it inwards to get the best possible fit under the gearbox cover.

The rest of the time I spent making M8 studs to fit the bulkhead

securing rivnuts of the gearbox cover. The reason for doing this was

to get accurate marks on the gearbox cover to indicate where to drill to fit

he cover to the bulkhead. The studs are inserted in to the rivnuts to

protrude in to the cockpit but not touch the cover. The ends of the studs

was covered in engineers blue. The gearbox cover was flange was covered in

masking tape. The cover was put in place over the gearbox and as centrally

as possible to the bulkhead aperture. The studs were wound forward

until they touched the flange of gearbox cover. The transfer of engineers

blue to the masking tape indicates where the flange should be drilled.

|

|

24/04/2006

2hrs Gearbox Cover |

I manages to sneak a couple of hours today.

I had to revisit the marking of the gearbox cover because I managed to

smudge one of the marks and to be accurate I felt it best to re-do them.

I used the same method as yesterday which gives a clear indication of he

position of the bolt hole to be drilled. I drilled the bottom hole on

either side with a pilot drill and then opened this out to 9mm. To mark the

top central bolt I inserted a shorter stud in to the hole and marked the end

with engineers blue. I made sure that only a little of the stud protruded

through the foam and was not touching the gearbox cover as I placed it

over the gearbox I refitted the gearbox cover securing it in place two long

bolts and tightened it up. tightening the bolts pulls the gearbox cover

forward compressing the seal. I tightened the bolts sufficiently until the

top of the gearbox cover came in to contact with the stud. the transfer if

the engineers blue marked where the top bolt hole should be drilled. I

took the cover off again and drilled the hole as before. I

refitted the cover to check the hole alignments all were perfect.

I have to repeat this for two more holes tomorrow.

|

|

27/04/2006

7hrs Gearbox cover Front Bulkhead |

I've made steady, if not fast, progress on

fitting the gearbox cover over the past 2 days. I've finished all the

holes in the front of the cover and bolted it up tight to the bulkhead.

I have drilled through the side flanges of the cover through the floor

boards ,making sure i did not hit any hidden obstructions under the floor

boards . I managed to match up the holes securing the front of the

prop shaft cover with the overlap of the gearbox cover so that 1 bolt

secures both together. I positioned a second securing bolt for the

rear of the gearbox cover, so that it came half way between the chassis

plate and the gear box supporting cross member. The rest of the cover

was secured with holes at approx 5½" centres. The gearbox cover was secured

to the floor boards using M5 PAN head screws , penny washers and nyloc nuts.

This was only a trial fit to allow me to mark the gear lever aperture and

mark where to trim the gear lever hole to get full range of operation

without fouling the cover. To get these adjustments correct involved

several removal and re-fitting of the gearbox cover. During one of these

operations today, I found that two of the Rivnuts in the bulkhead had pulled

through. The bulkhead metal is very thin and constant fitting and

removal of the cover had enlarged the hole so that the rivnuts had

come loose and pulled through the metal. I would still recommend using

rivnuts but I would fit them BEFORE fitting the bulkhead if I were to

do it again. I fixed the problem by fitting new rivnuts backed

a washer to give more support and depth for the rivnut to grip.

Despite take care over the measurement and positioning of the gear

lever hole I got it slightly wrong. I had allowed, as I thought,

enough margin in the size and position to compensate fro the compression of

the seals and the final position of the gearbox cover. However now

that it is in place I was too far forward and slightly off at a

diagonal. with the cover in its final position I remarked the hole

correctly removed the cover and cut out the new hole for the gear lever.

to correct the mistake and end up with a circular hole I could either

enlarge the gear lever hole, or keep the new hole size and add a little

filler to one side. I chose the latter. I made a tube of

the correct diameter to act as a former and preserve the circularity of the

hole. I inserted it in to the cover and greased it lightly so that it would not stick

to the filler. I made bed for the filler by sticking masking

tape to the inside of the cover and up against the tube. I

filled the gap with P38 filling compound and left it to set.

|

|

30/04/2006

6hrs Gearbox Cover Transmission Cover Gearbox |

There is light at the end of the

"transmission" tunnel. The filler had set and the grease had stopped

the former sticking to the filler. I sanded down the filler to the

contour of the gearbox cover. both inside and out. It was a little low

in a couple of places so I made up some more and applied it again.

When it had set I rubbed it down again until it was smooth and flush with

the contour. A light coat of grey paint primer and you couldn't tell

there was ever a problem. I refitted the gearbox cover and tightened

it up to the bulkhead. this time the hole for the gear lever was perfectly

placed. I took the opportunity to cut the top of the gear lever to

length so that the sleeve fro the new gear knob was correctly placed.

Now that it s cut to size, I'll get in touch with John Hopkins to pin

the sleeve to the gear lever. Time to take the cover off

again and fir the rubber seal to the floor. I lid the seal along the

floor in the approximate position. Marked where the first screw hole would

come on the seal and punched a hole in it using a single hole punch. O

placed a screw through the hole and in to the hole in the floor board and

progressed to the next hole, repeating the process until I reached the far

end. I the started at one and stripped of a short section of the

backing. I stuck the seal in place, making sure the screw lined up with the

corresponding hole, I progressed along the seal repeating the process

until I reached the far end. At the far end I cut the seal to length with a

pair of sharp scissors. I repeated the process for the seal on the

other side. With the floor seal in place the gearbox cover sits higher.

The bulkhead holes need to be slotted so that the bolts line up. I use the

same method that I used for the original holes. I placed masking tape

on the face of the gearbox cover flange and fitted the cover approximately

in place. I inserted some studs dipped in engineers blue from the

engine compartment side of the bulkhead and screwed then in until they

touched the cover. The transferred blue marked where the flange needed to be

drilled to align with the bolt. I drilled the corresponding hole in

the flange and slotted it until it met the original hole. I repeated

this for the remaining 4 holes in the flange to attach the cover to the

bulkhead. The slots allow the cover to take up its correct position as

the seals are compressed when the cover is bolted to the floor.

Similarly the holes in the flange to bolt the cover to the floor need to be

slotted to accommodate the compression of the bulkhead seal as the cover is

tightened to the bulkhead. A similar process to marking the bulkhead

holes can be done with the floor holes. Dip the end of a bolt in engineers

blue, insert it in the hole from underneath the car. The transferred

blue dot marks the position of the bolt on the flange. I drilled out the hole

and then slotted the original hole. I trial fitted the

cover to check the slot alignments with the hole the floor all was OK.

|

| |

I decided some time ago that it would

be easier to drain and fill the gearbox with the gearbox cover off so the

last job today was to do just that.

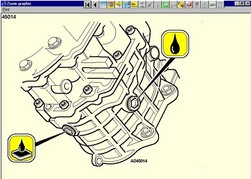

The drain plug on the Getrag box

is a 17mm HEX socket plug in the bottom of the gearbox. The filler plug is

the same sort of 17mm plug on the RHS if the gearbox about half way up.

I undid the drain plug and was pleased to see the oil was clear and clean.

The drain plug is magnetic and had the usual whiskers of metal stuck to it

but no more than normal. I left the oil to drain overnight. |

|

|

|

|

|

Total hours this month = 29 |

|

|

Total hours to date =1609.0 |

| |

|

|

|

|